Who We Are

About

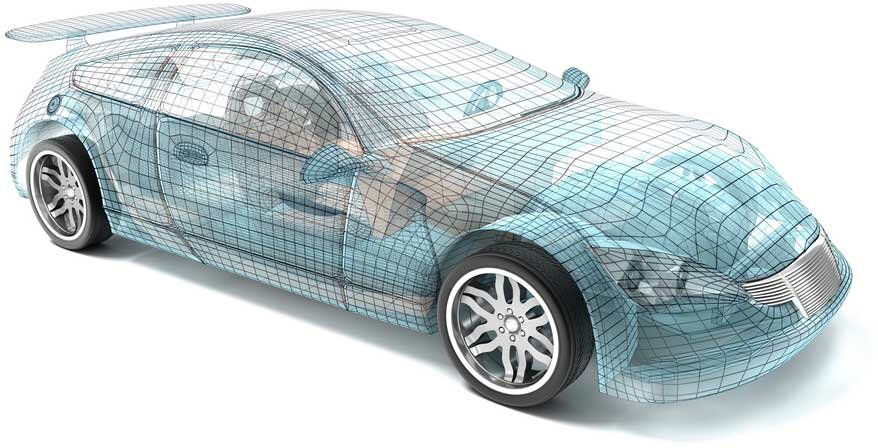

Coventive Composites is a specialist independent consultancy, providing technical expertise and access to pilot-scale equipment and testing facilities to help our clients develop and commercialise novel composite materials and components.

Our expert advice and technical support cover all aspects of the product development lifecycle.

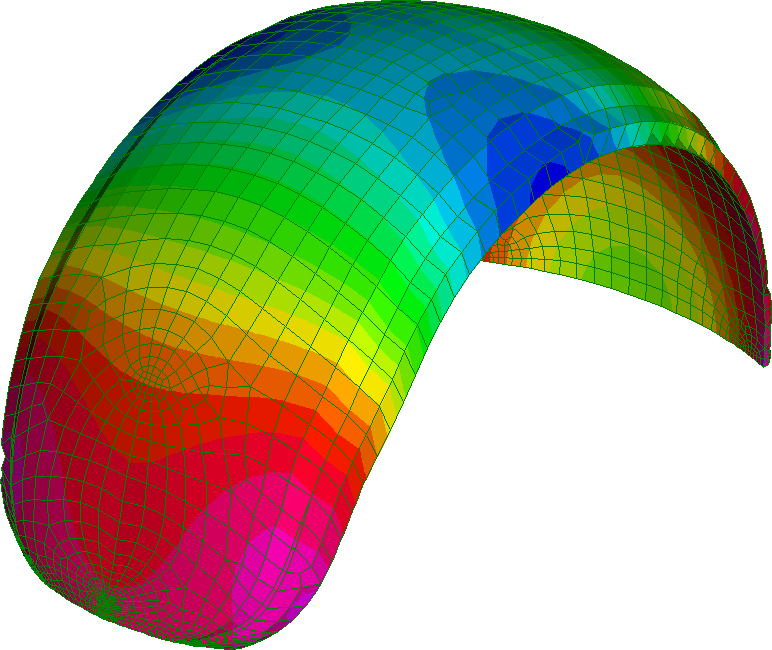

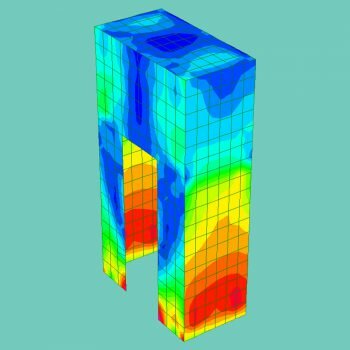

From our in-house innovation centre, our team of scientists and engineers offer a combination of services spanning market intelligence, materials and process development, design and structural analysis, pilot-scale manufacturing and prototyping, materials characterisation and testing, and training.

Our offering is flexible, to suit our clients’ individual requirements. We carry out short term projects and one-off assignments, lead extended multi-stage programmes, and enter into long-term development partnerships.