Can I have it in composites?

15th August 2019 Ben Hargreaves

In this explainer, we’re going to focus on the fundamental choices which need to be made with regard to materials and part production methods and consider the links between the two.

Types of Polymer Matrix

5th July 2019 Elliot Fleet

There are many different types of polymers that can be used as a matrix for composite materials. In this explainer, we’ll look at ways in which these materials can be categorised and highlight the key differences between them. Let’s start with perhaps the most fundamental categorisation… Thermoplastic or Thermosetting? Thermoplastic Thermoplastics can be heated and […]

The Opportunities for Thermoplastic Composites

31st May 2019 Chris Hare

The primary driving force behind the emergence of thermoplastic composites into the mainstream is the automotive industry. And the things that drive the automotive industry are weight saving and low cost, so how do thermoplastic composites meet the challenge?

GRP Tank Covers: How to meet regulatory requirements in a cost-effective way

4th April 2019 Ben Hargreaves

GRP covers are widely used throughout the water-treatment industry due to their combination of mechanical performance, corrosion resistance, chemical resistance and low weight.

Finite Element Analysis: How to create a great model

18th March 2019 Romilly Close

Finite Element Analysis (FEA) is the numerical modelling of structures by breaking them down into a discrete number of ‘elements’. Elements share nodes and at these nodes physical fields such as displacement are calculated. The model is then resolved for a vector of displacements, and from this the effect of loading on the structure can be obtained.

What is Finite Element Analysis?

7th March 2019 Romilly Close

FEA is a computer-based numerical-analysis technique which involves breaking down large, complex structures (‘models’) into a mesh of discrete elements. The elements are connected to each other, at points called ‘nodes’, creating a continuous surface. The model is ascribed some material properties; it is restrained (to allow the forces to act in a physically realistic manner); a loading scenario is applied; and the FEA software generates sets of equations according to the shape of the elements and material properties.

What is Composite Ballistic Armour?

1st February 2019 Chris Hare

Ballistic Armour is a generic term for a protective layer of material that protects a person or object from projectiles. The common requirement of all systems is to dissipate the projectile energy with minimal damage to the target. This requirement for energy dissipation is where multi-layer composites can provide some advantages.

Compression Moulding: How to make High-performance Thermoplastic Composites

7th November 2018 Francisco Saraiva

An in-depth look at how compression moulding can be used for the production of high-performance thermoplastic composite components, highlighting technique as a precise and potentially rapid process for producing high-quality composite parts in a range of volumes.

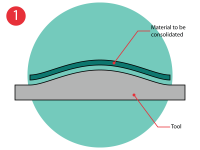

What is Vacuum Bagging?

20th September 2018 Joe Carruthers

Vacuum bagging is a very flexible process for consolidating fibre-reinforced polymers of a wide range of shapes and sizes.

What is Compression Moulding?

19th July 2018 Joe Carruthers

Compression moulding is a precise and potentially rapid process for producing high quality composite parts in a wide range of volumes. It typically employs a matched metal tool in a heated (hydraulic) press to consolidate sheet materials or moulding compounds at relatively high pressures.

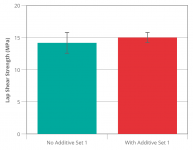

Composite Material Testing – The Challenges of Batch-to-Batch Variation and How to Manage Them

29th June 2018 Elliot Fleet

Statistics is a branch of mathematics that deals with managing data and evaluating logically how well it fits a preconceived pattern or model. Similarly a large part of composites R&D and materials science is concerned with generating data and using it to support a hypothesis. The use of statistical methods is therefore absolutely critical to […]

What is Resin Transfer Moulding (RTM)?

25th April 2018 Joe Carruthers

Resin transfer moulding (RTM) is a closed-mould process for manufacturing high performance composite components in medium volumes (1,000s to 10,000s of parts).

What is Dynamic Mechanical Analysis (DMA)?

22nd April 2018 Gary Foster

Dynamic Mechanical Analysis or DMA for short, is an extremely versatile and flexible analytical technique for measuring the physical properties of a range of materials.