Fibre Reinforced Thermoplastic Tapes

Manufacture of Complex Structures

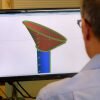

Automated tape-laying or winding using fibre-reinforced thermoplastic tapes has advanced significantly over recent years. This photo above demonstrates that it is now possible to wind engineering structures with variable diameters. One of the advantages of using thermoplastics is that such parts can be subsequently post-formed to create more complex shapes such as components with a 90° angle. The use of fibre reinforced thermoplastic tapes provides outstanding mechanical performance, a clean manufacturing process, low waste and a recyclable product.

Tape Manufacture

Coventive has developed a process and pilot line for manufacturing a variety of fibre reinforced thermoplastic tapes for use with automated tape-laying. Our process can be easily adapted to allow for a range of different fibre reinforcements and polymer matrices to be manufactured. Bespoke tapes can be made to fit the specific requirements of an application.

Future

More complex shapes can be reinforced, manufactured and subsequently formed using automated tape laying technology. Advancements in process speed and tape placement will further progress the take-up of the technology.

Downloads

Capabilities

Fibre Commingling

The blending of two different yarns to produce a single mixed yarn - used for producing hybrid reinforcements for composites such as carbon/glass or carbon/aramid

Microwave Heating

We have developed techniques for rapidly and uniformly heating thermoplastic composite and self-reinforced polymer (SRP) sheet materials using microwaves

Thermoplastic Pultrusion

We have pilot lines for the thermoplastic pultrusion of unidirectional fibre-reinforced tapes and rods, including an optional facility for the chopping thereof

Industries

Mass Transport

Composites are routinely employed in trains and buses, most notably in train cabs and passenger interiors. As with other transport sectors, the fire requirements of the rail industry are very stringent, particularly for underground trains. This is another sector in which Coventive is working to introduce new lightweight, fire-safe composites.

Sports and Leisure

Sporting goods are all about performance. Materials that can make a piece of equipment lighter, stiffer, stronger, or more impact resistant can often provide a competitive advantage. Coventive has worked across a wide range of such applications including footwear, protective apparel, and sporting equipment.

Found this article useful? We have a full range of services to help you...

Pilot-Scale Manufacturing & Prototyping

Our suite of pilot-scale manufacturing facilities are at your disposal - prepregging, compression moulding, resin transfer moulding, injection moulding, and many more.

Making composites...

Materials & Process Development

Whether it's thermosetting or thermoplastic composites, biocomposites or nanocomposites, we can help you develop a material or process that meets your requirements.

Developing composites...News