About

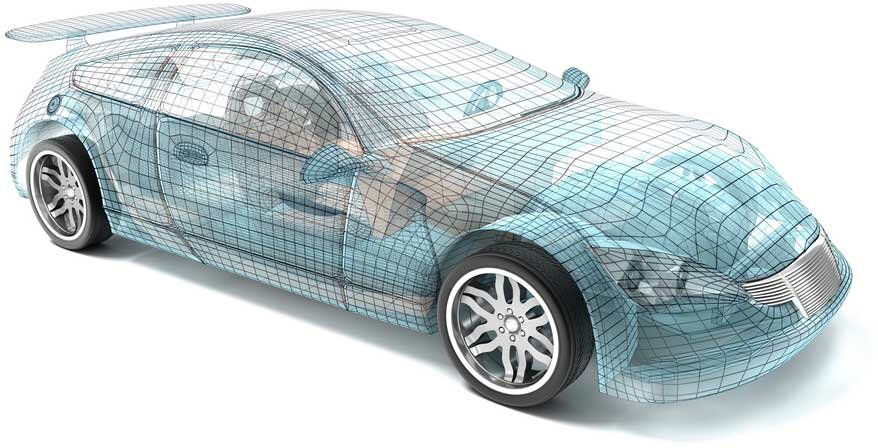

Composite material innovation has become a crucial area of focus in advancing product development across industries. The field integrates technical expertise and specialized facilities for pilot-scale testing, enabling the exploration and commercialization of new composite materials and components.

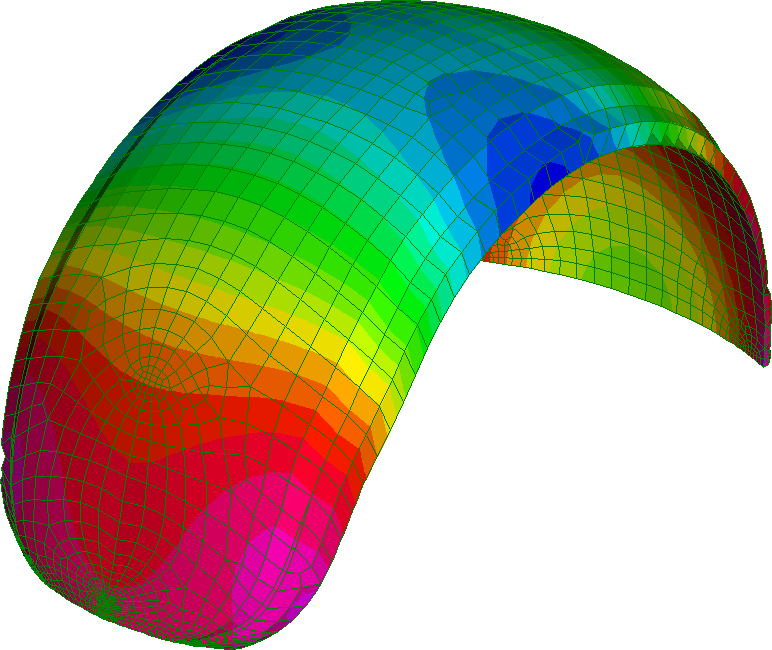

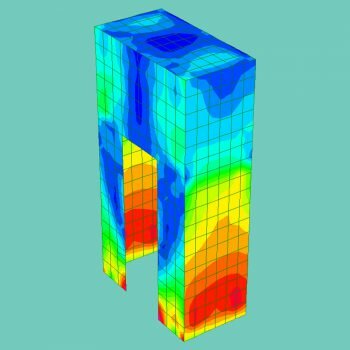

Throughout the product development lifecycle, from initial concepts to manufacturing, experts in composites offer guidance and support, including insights into market trends, advancements in materials and processes, design optimization, structural analysis, and prototype creation. Comprehensive materials testing, characterization, and tailored training further enrich this sector, helping clients refine and realize their innovative ideas.

Flexibility is a hallmark of this field, allowing for both short-term research projects and long-term developmental partnerships, tailored to meet the unique needs of various applications.