Long Natural Fibre Thermoplastic (LFT)

Natural Fibre Pellet Development

Long natural fibre thermoplastic, injection-mouldable pellets are a composite of natural fibres (e.g. flax, hemp, jute) in a polypropylene matrix. They have been developed by Coventive as a cost-effective alternative to long glass fibre thermoplastic (LFT) products in, for example, automotive applications.

Glass fibres are relative heavy, derived from non-renewable sources and cannot easily be recycled. By contrast, natural fibres are less dense than glass and have a lower environmental impact. They also have a similar stiffness to glass fibres.

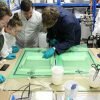

The pellet format and method by which they are produced also helps to preserve the reinforcing properties of the natural fibres; these are often compromised in other more aggressive compounding processes.

The technology continues to be refined. Please contact us if you would like further details or to discuss how you might evaluate or deploy the technology.

LFT Manufacture

The pellets are typically a 50:50 mix by volume of natural fibres and polypropylene fibres. They are currently produced using Coventive’s in-house pilot line at a length of between 5 and 25 mm, depending upon the requirements of the user.

The pellets can then be injection moulded using standard equipment. Because natural fibres are less abrasive than glass, they also generate less tool wear.

Downloads

Download case study (PDF)Capabilities

Biocomposites

High-performance reinforcements and resins for composites that are produced from sustainable, non-fossil fuel resources - natural fibre reinforcements and bio-derived resins

Injection Moulding

A high volume manufacturing process in which a molten thermoplastic (sometimes containing short reinforcing fibres) is injected into a mould at high pressure

Materials Evaluation

Using our suite of testing and analysis equipment, we can evaluate the performance of polymers and composites, and provide guidance on further improvement

Process Development

The development of processes for manufacturing composite materials such as prepregs, tapes and moulding compounds, including the design and construction of pilot lines

Production Trials

We have a wide range of processing equipment for undertaking small-scale production trials - prepregging, injection moulding, compression moulding, and more

Thermoplastic Pultrusion

We have pilot lines for the thermoplastic pultrusion of unidirectional fibre-reinforced tapes and rods, including an optional facility for the chopping thereof

Industries

Automotive

Whilst composites are used in mainstream automotive applications, they tend to be restricted to low-performance semi-structural parts. Material costs, cycle times and production volumes generally limit their use for structural components. Coventive is working to develop new materials and processes that overcome these limitations.

Consumer Goods

Multifunctional composites open-up some exciting possibilities for consumer goods - for example, unique aesthetics, electrically conductive polymers, composites with high heat transfer, and materials with self-sensing capabilities. Coventive is working to explore how composites and nano-composites can provide such capabilities.

Found this article useful? We have a full range of services to help you...

Materials & Process Development

Whether it's thermosetting or thermoplastic composites, biocomposites or nanocomposites, we can help you develop a material or process that meets your requirements.

Developing composites...News