Aluminum composite material has become essential in modern construction, design, and manufacturing. This innovative material offers strength, versatility, and aesthetic appeal, making it a popular choice in various applications. In this article, we delve into what is aluminum composite material, explore its manufacturing process, examine the benefits of aluminum composite material panels, and discuss its role in educational settings. We also provide insights into the best practices for selecting aluminum composite products and how to connect with reliable aluminum composite material suppliers.

What is Aluminum Composite Material?

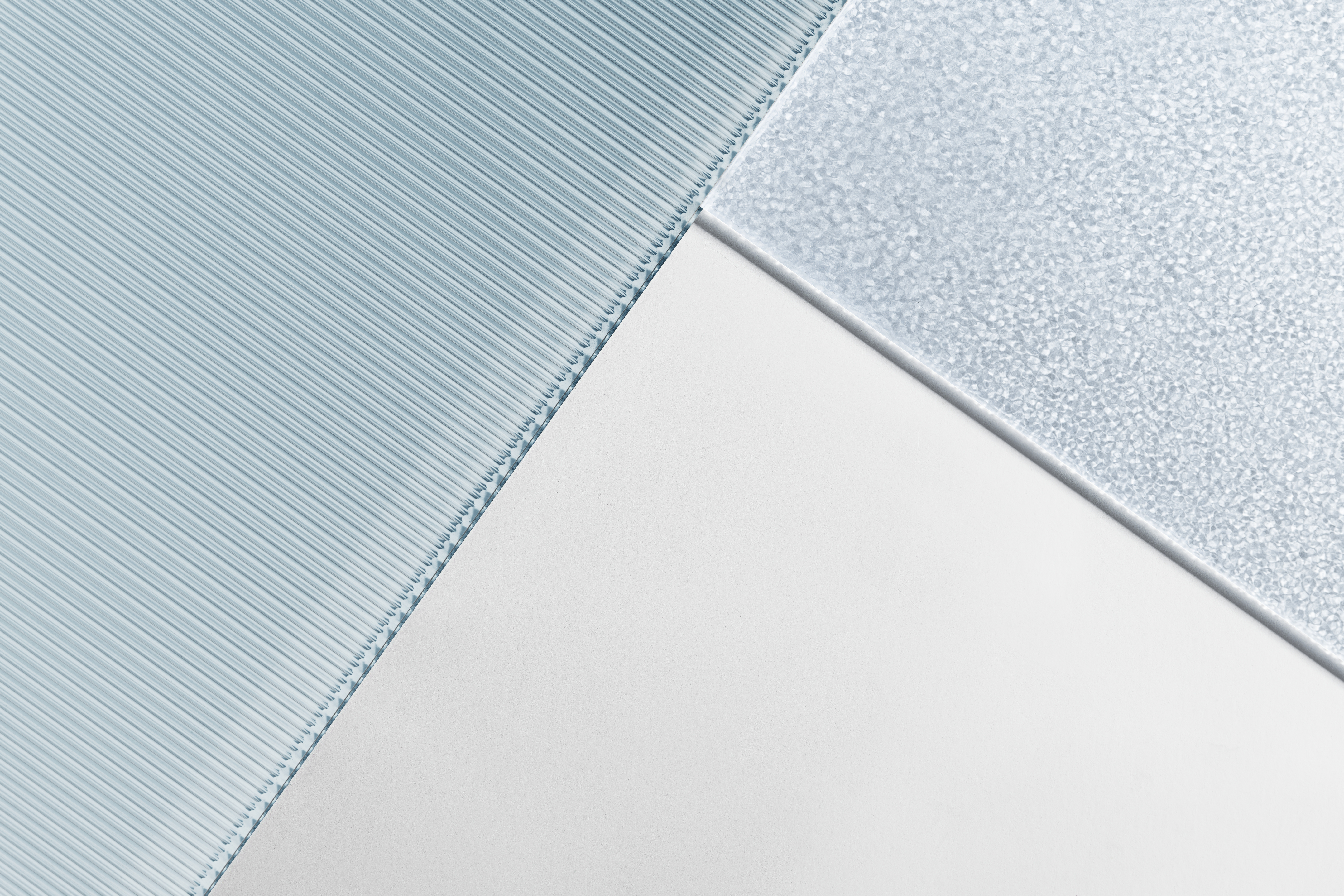

Aluminum composite material (ACM) is a sandwich panel of two thin aluminum sheets bonded to a non-aluminum core. This core can be made of various materials, such as polyethylene, fire-resistant mineral-filled cores, or other specialized materials. The result is a lightweight yet robust panel with excellent durability and thermal efficiency. The Wikipedia page on aluminum composite material is a valuable resource for more detailed technical information on this material.

Components and Manufacturing Process

The manufacturing process of aluminum composite panel material typically involves the following steps:

-

Aluminum Sheets Production: High-quality aluminum is rolled into thin sheets. These sheets are treated to enhance their durability and resistance to corrosion.

-

Core Material Selection: The core material is chosen based on the intended application. For instance, fire-resistant cores are used in public buildings, while polyethylene cores might be selected for decorative cladding.

-

Bonding Process: The aluminum sheets and the core are bonded using specialized adhesives under controlled conditions, ensuring a uniform and stable composite panel.

-

Finishing and Coating: The final step involves applying protective and decorative coatings to enhance the panel's appearance and extend its lifespan.

This process creates a strong, lightweight product and is highly adaptable for various construction and design applications.

Applications in Education and Industry

Educational Use and Research

In academic settings, aluminum composite material is an excellent subject for study in materials science, engineering, and architecture programs. Universities and technical institutes incorporate modules on composite materials into their curricula to help students understand modern manufacturing techniques and sustainable material choices. Laboratories and research centers use ACM samples to conduct tests on structural integrity, thermal insulation, and fire resistance, providing hands-on experience that bridges theoretical knowledge and practical application. Additionally, many research facilities utilize a dma machine to analyze the dynamic mechanical properties of composite materials, offering precise measurements that further enhance students' practical learning experiences.

Architectural and Industrial Applications

Aluminum composite material panels are widely used in architectural cladding, signage, and interior design due to their versatility and aesthetic qualities. Modern buildings, airports, shopping centers, and public installations frequently feature ACM to achieve sleek, modern facades with superior weather resistance. Using aluminum composite material panels not only enhances building performance but also contributes to energy efficiency and sustainable design.

For more information on industry standards and testing methods related to composite materials, refer to the ASTM International guidelines, which outline the standards for materials like ACM.

Advantages of Using Aluminum Composite Material

Durability and Strength

One of the primary benefits of ACM is its strength-to-weight ratio. The combination of aluminum skins and a resilient core provides excellent structural stability without adding excessive weight. This makes it an ideal choice for applications where strength and lightness are critical, such as aerospace, transportation, and modern construction.

Aesthetic Appeal and Versatility

The smooth surface of aluminum composite material panels allows for a high-quality finish suitable for functional and decorative applications. The material can be easily printed, painted, or anodized, offering designers various creative possibilities. Its sleek appearance is particularly valued in contemporary architecture and urban design.

Environmental and Economic Benefits

ACM is not only cost-effective due to its lightweight properties but also contributes to environmental sustainability. The energy efficiency achieved through its thermal insulation properties can reduce building heating and cooling costs. Additionally, many aluminum composite material suppliers now offer eco-friendly panels incorporating recycled materials, supporting the global push toward sustainable development.

How to Choose the Right Aluminum Composite Material Supplier

When selecting a supplier for aluminum composite material panels, it is essential to consider several factors:

-

Quality Assurance: Look for suppliers that adhere to international standards and have certifications from recognized bodies.

-

Product Range: A reputable supplier should offer various ACM options, including different core materials and finishes, to meet diverse project needs.

-

Customer Support and Technical Guidance: Effective support and technical consultation can be crucial in selecting the right material for your application.

For businesses and educational institutions looking for high-quality ACM, visiting Coventive Composites can provide valuable insights into available products and industry expertise.

Conclusion

The exploration of what is aluminum composite material reveals a product that is at the forefront of modern material technology. With its robust construction, versatility, and economic benefits, ACM is vital in educational and industrial applications. Whether you are a student studying material science, an architect designing a modern facade, or an industry professional seeking reliable aluminum composite material suppliers, understanding the properties and benefits of ACM is essential.

By integrating ACM into educational curricula and practical applications, we can foster innovation and sustainable practices in construction and design. As technology evolves, the continued study and application of aluminum composite material panels will undoubtedly play a significant role in shaping the future of material science and engineering.

For more detailed information and the latest updates on ACM products, visit Coventive Composites.

By embracing the advancements in composite materials, we empower the next generation of innovators and engineers to build a sustainable and efficient future.