Services

Design & Structural Analysis

Composite materials provide considerable design freedom. By exploiting the opportunities they present in terms of material selection and orientation, it is possible to tailor the properties of a composite according to the requirements of a given application. However, this also means that composite design can be relatively complex, with an increased number of design variables and material characteristics to manage.

Our designers and analysts can help you select the right material configurations for your application, as well as performing the necessary calculations or simulations to evaluate your product’s fitness for purpose against design codes or other requirements.

Capabilities

Computer-aided Design (CAD)

Our design engineers can help you visualise your products using computer-aided design (CAD), or can prepare your existing CAD models for structural analysis

Design Codes and their Application

Where there is a requirement to design a composite component in accordance with a specific standard or norm, we can work with you to ensure design compliance

Design Verification

We can provide an independent verification that the design of your composite product is fit-for-purpose, or advise you on modifications that might be necessary

Failure Investigation

We can undertake investigations to understand the reasons behind the failure of a composite component or structure - both in-the-field studies and supporting laboratory analysis

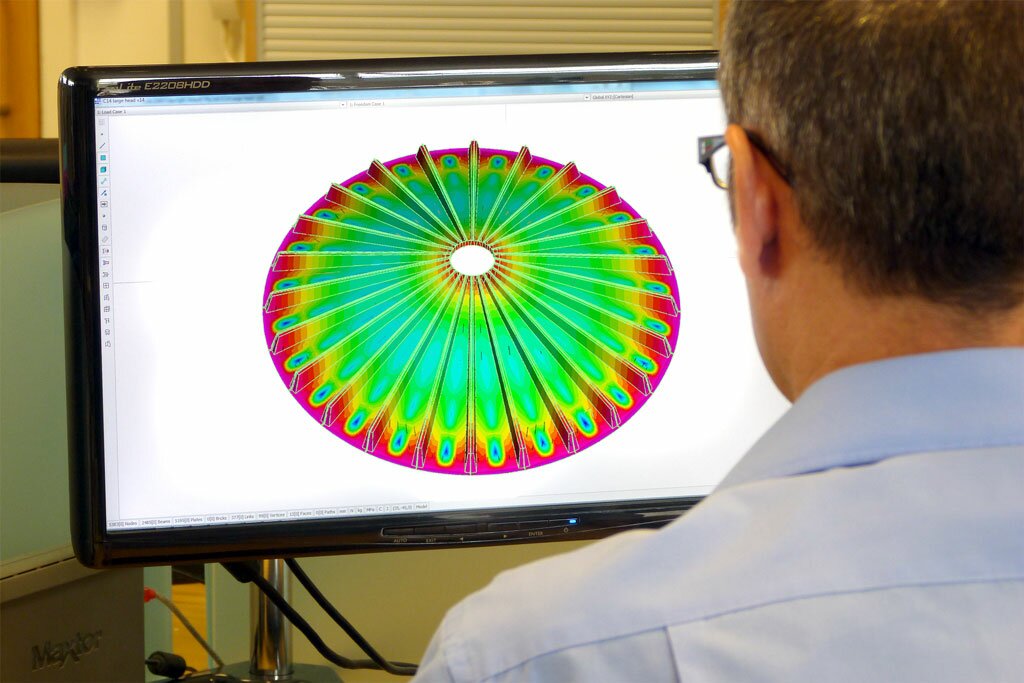

Finite Element Analysis (FEA)

A computational tool for simulating and analysing the response of a structure to applied mechanical or thermal loads - used for design verification and optimisation

Material Selection

The flexibility of composites derives from the wide range of material choices - we can guide you in the selection of reinforcements, resins, cores, additives and coatings

On-site Inspection

We can undertake on-site inspections of your composite assets to assess ongoing fitness-for-purpose and, if necessary, suggest remedial action

Associated Case Studies

Failure Analysis of a GRP Tank

Glass-reinforced plastic (GRP) tanks/vessels are used to store liquids underground. Catastrophic failure of the tank can lead to serious consequences, even if the contents of the tank are not hazardous. Therefore, during the installation phase, a tank must be handled very carefully; it is important that due consideration is given to the protection of the […]

Finite Element Analysis of GRP Antenna Shrouds

GRP antenna shrouds and enclosures have been widely used by the mobile-telecoms industry for a number of years, due to their combination of RF transparency and design freedom.

Structural analysis of GRP tank covers

GRP covers are widely used in the water-treatment industry to help control odours. The covers need to be able to withstand the local conditions of wind and snow and, depending upon the specific location, may also be required to handle personnel loads, impact loads etc.

Can we help you with your design & structural analysis requirements?

Complete the form, or use the contact details and one of our composites experts will be in touch.

- +44 (0) 1246 266244

- — OR —

*We'd like to send you occasional updates about our products and services, special offers, news and events. We'll always keep your personal details secure and will never share them with third parties for marketing purposes. You can unsubscribe at any time. For further details on how we may use your data, please visit our Privacy Policy.

Share this

What our clients say

They were selected as the development partner for novel materials structures and were instrumental in supporting strategic market analysis, leading to development programs on unique products. Their staff engaged and worked effectively in a multi partner framework engaging effectively with adjacent industrial partners. As a result it was possible to significantly increase project velocity, broaden the scope of the work and evaluate the market relevance of development ideas. They continue to a valued development partner.

Amongst all the providers of technical support to users and intended users of composite materials, they offer a unique blend of expertise, skills and knowledge in this area that has been recognised by RAPRA and its members. RAPRA is therefore proud to have them as a key part of its Technical Support Network that it uses to serve members and wider Industry.

As a small company with a small budget we have been able to utilise the expertise of their consultants Chris Hare, Joe Carruthers and Ben Hargreaves. Through their in-depth knowledge and understanding of both composites and business needs, our composites for footwear have improved in strength, durability and manufacturability.

We commissioned them to review the projected demand for composites among UK based automotive suppliers and the associated opportunity gaps in the UK composites supply chain.

The purpose of the research was to firstly establish views on the adoption of volume composites amongst automotive OEM’s and secondly, to assess if Tees Valley could be positioned to host known ‘energy intensive’ segments of the composites supply chain, such as precursor and carbon fibre manufacture. Tees Valley is Western Europe’s 2nd largest chemical producing region and offers embedded power generation and private wire networks enabling companies to benefit from lower power and utilities costs compared to many other UK manufacturing locations.

We selected them to deliver the work based on their strong insights and contacts within the UK’s composites industry as well as their expertise in the application of composite solutions in automotive and other key UK advanced manufacturing segments

We are truly delighted with the resulting intelligence as it gives Tees Valley a clearer view on the investor opportunities that best align with the unique assets and skills base in our area. We would have no hesitation in recommending them and in using them again in the future.