Can I have it in composites?

- 15th August 2019

- Ben Hargreaves

- Reading time: about 10 minutes

At Coventive, we are often approached by companies seeking advice as they aim to develop new polymer composite components.

Whatever their background, they typically fall into one of two camps:

- those who currently make widgets out of metal but, for various reasons, now wish to offer an equivalent polymer composite widget, or:

- those who don’t currently make widgets, but would like to enter the widget-making business and believe that composite materials would be well-suited to the demands being placed on those widgets.

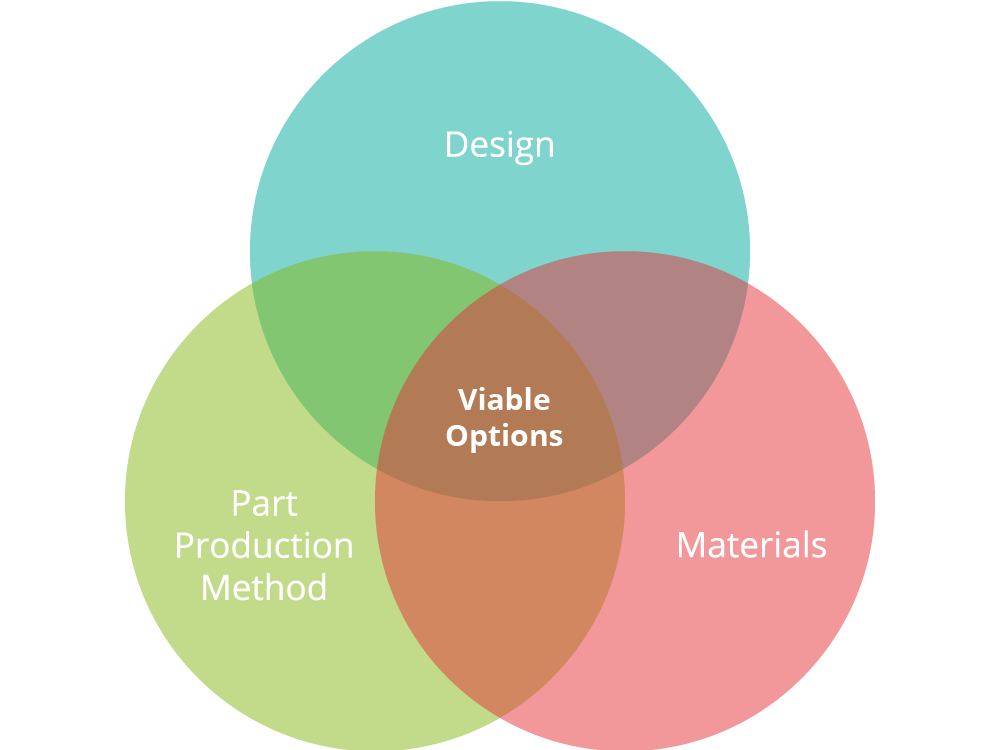

In such cases – and particularly for those companies who fall into the first camp – it is important to stress the importance of designing their widget in order to best utilise the properties of composites. Simply replicating what they are already doing in metal is unlikely to play to the strengths of polymer composites. However, this design process cannot be done in isolation. Perhaps more so than with any other materials, with composites, it is important to have a holistic view which takes into account not only the part design and materials of construction but also the production method required to manufacture those parts in the necessary volumes.

In this explainer, we’re going to focus on the fundamental choices which need to be made with regard to materials and part production methods and consider the links between the two. (We’ll save designing with composites for another Explainer!)

The three key questions

The range of materials and processing methods is pretty extensive and so, to start with, we need some means of ruling out the non-starters. To do this, it helps to consider the following key questions which, between them, set the boundary conditions within which our component must fall:

- What are the mechanical requirements (strength & stiffness) of the component?

This dictates the choice of reinforcement fibre and the required fibre volume fraction which, in turn, restricts the choice of production processes. - What are the environmental conditions?

This dictates the choice of matrix material. - How many do we need to produce?

This limits the choice of production process.

Armed with the answers to these questions, we can now begin to consider the material and processing options in some more detail.

Selecting the materials

Which reinforcement should I use?

The overwhelming majority of composite components manufactured today (~90%) use glass fibre reinforcements, with carbon fibre reinforcements accounting for most of the remainder. However other fibres are coming increasingly into play and therefore, particularly for the new entrant, it is worth considering all of the available options.

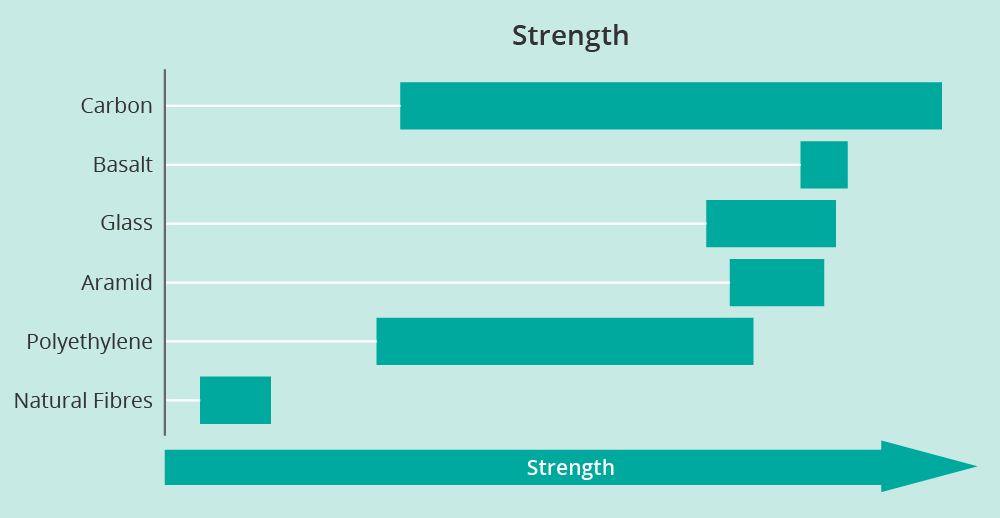

The following diagrams give an indication of relative stiffness and strength of common reinforcement fibres. From these, we can see that, as we ramp up the performance requirements, our choice of reinforcement becomes more limited.

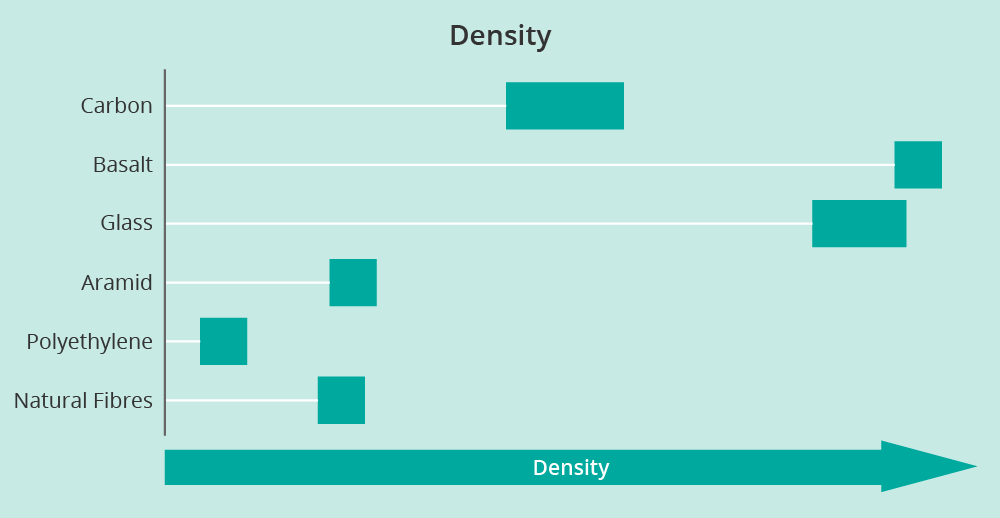

However, if our target performance is somewhere in the middle, we are still left with several options. Given that one of the main drivers for the use of composites is weight reduction, differences in fibre density are worth considering.

Another factor which can come into play at this point is the availability (or otherwise) of the reinforcement in the correct format (e.g. woven textile, stitched multi-axial, random short fibre), as this will have a significant influence on the attainable properties and can further restrict the choice of production processes (we’ll discuss the pros and cons of different reinforcement formats in later explainers).

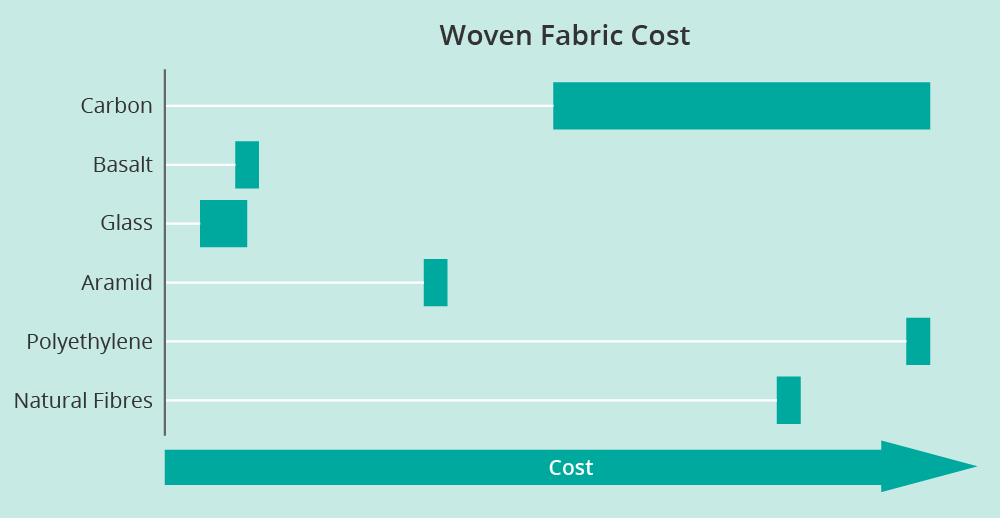

And finally, of course, there is the not insignificant matter of cost – which goes some way to explaining the continuing proliferation of glass as a reinforcement material!

…and which matrix material should I use?

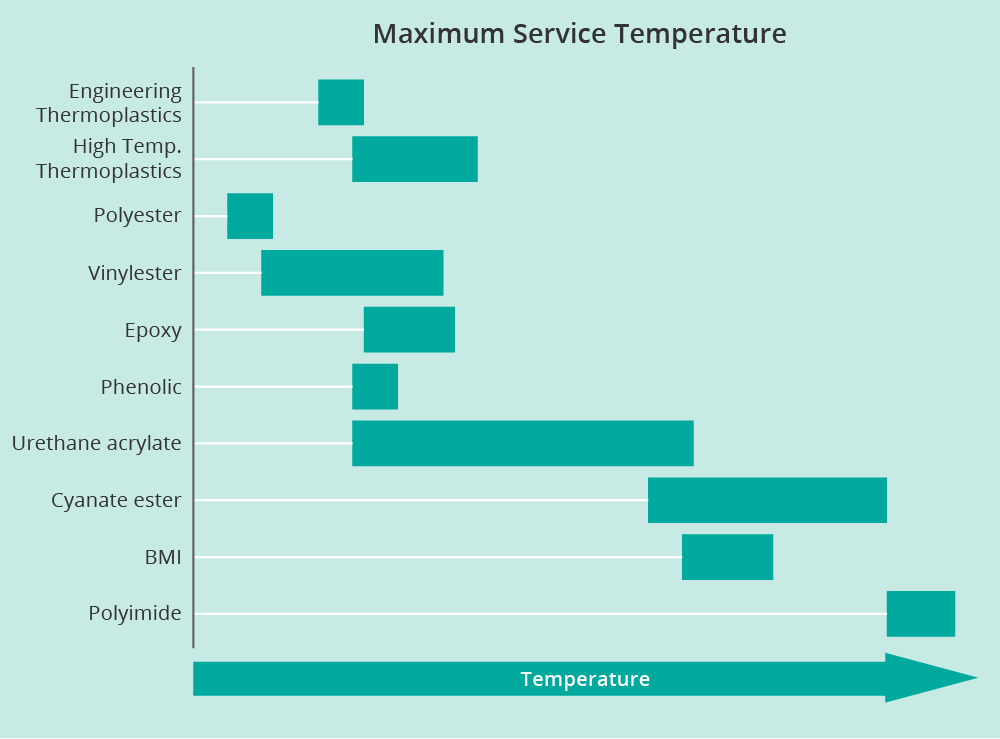

Often the most important consideration here is maximum service temperature and, as with the reinforcement materials, we find that as we ramp up the demands being placed on the component, we reduce the number of suitable options.

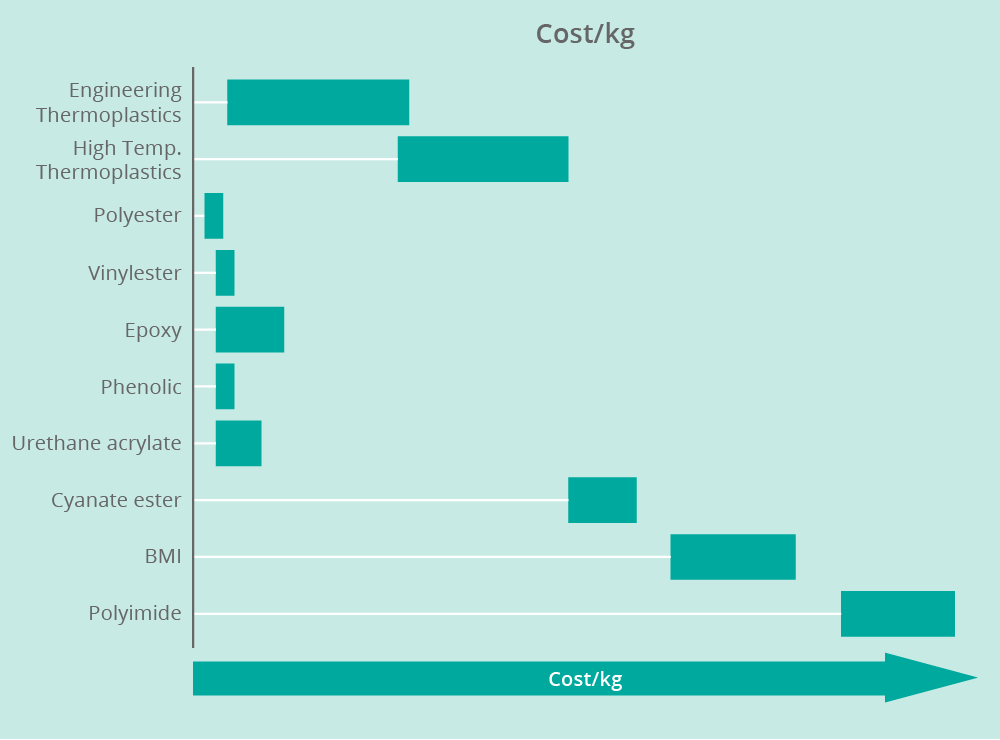

…and those options become increasingly expensive.

Other considerations include:

- chemical compatibility;

- weather resistance (UV, water ingress, temperature fluctuations, etc.) and;

- fire, smoke & toxicity performance.

Selecting the processing method

Which processes go with which materials?

As we can see from the table below, the processing options for the majority of thermoplastic composites remain the same, regardless of whether we are talking about engineering thermoplastics or the more exotic high-temperature grades. However, it is worth noting that equipment and tooling costs can rise sharply when processing temperatures of above ~300°C are required.

For thermosets, however, the choice of process is more dependant upon the material. In some cases, a process might only be feasible with certain resins. Prepregging, for example, relies on being able to “pause” the cure reaction to give a material which is flexible and tacky at room temperature, which then fully solidifies at elevated temperature. This can be achieved with epoxies (for example), but not polyesters.

In other cases, the restriction arises due to mismatches between cost, production volume and part quality. For example; due to high materials costs, BMI resins and polyimides are typically only found in low volume, high performance, high value applications. Therefore a process like pultrusion – which usually only becomes economically viable for the pultruder when tens of thousands of metres of profile are being manufactured – is not really compatible, even though it is technically feasible. Likewise, whilst it might (just) be feasible to produce components by hand layup using low viscosity cyanate ester resins, in reality, if the application demands the use of such a specialist resin, it is similarly likely to require the levels of mechanical performance, dimensional accuracy and low-void content which hand layup cannot achieve.

| Polymer | Processing Methods | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Injection Moulding | Extrusion | Rotational Moulding | Hand lay-up / Spray lay-up | Infusion (Vacuum / RTM) | SMC / BMC | Prepreg Compression Moulding | Autoclave | Pultrusion | Filament Winding | |

| Engineering thermoplastics | ||||||||||

| High temperature thermoplastics | ||||||||||

| Polyester | ||||||||||

| Vinyl ester | ||||||||||

| Epoxy | ||||||||||

| Phenolic | ||||||||||

| Urethene acrylate | ||||||||||

| Cyanate ester | ||||||||||

| BMI | ||||||||||

| Polyimide | ||||||||||

So which processes are suited to making my widgets?

To answer this question, we need to look more closely at the cost, volume and performance considerations highlighted above. This is also where the part design comes into play as certain features and geometries cannot be achieved with certain processes. As highlighted in the opening section of this Explainer, in an ideal world, materials, process and design will be considered together. However this does not exclude the possibility that design restrictions will remain, which may mean some processes are not viable.

Invariably, there is no single right answer; it is a question of weighing up the options and deciding what works best for your situation. The following table gives an overview of the key considerations.

| Process | Equipment Costs | Tooling Costs | Production Volumes | Technical Notes |

|---|---|---|---|---|

| Injection Moulding | £££ – ££££ | ££ – £££ |

|

|

| Extrusion | £££ – ££££ | £££ |

|

|

| Rotational Moulding | ££££ – £££££ | ? |

|

|

| Hand lay-up / Spray-up | £ | £ – ££ |

|

|

| Vacuum Infusion | £ – ££ | £ – ££ | / |

|

| RTM | ££ – £££ | ££ – £££ |

|

|

| SMC / BMC | £££ | ££ – £££ |

|

|

| Prepreg compression moulding | £££ | ££ – £££ |

|

|

| Autoclave processing | ££££ – £££££ | £££ |

|

|

| Pultrusion | £££££ | £££ |

|

|

| Filament winding | £££ | £ | / |

|

In summary

Composite materials can offer a wide range of technical, economic and environmental benefits in a variety of applications across multiple sectors. However, there is no one-size-fits-all solution. Instead, it is important to understand the relationships between materials, manufacturing methods and part design and to recognise how your specific requirements will dictate the options open to you.

How can Coventive help

Our experts can provide support right across the product development lifecycle. To begin with, we can help you:

- improve your knowledge of composite materials, composite materials processing and designing with composites;

- identify key product requirements and appreciate how these will influence subsequent materials, design and production choices and;

- evaluate the technical and commercial feasibility of a range of potential solutions.

From here, we can provide follow-on support in a number of areas including:

- competitor activity mapping and technical benchmarking;

- project cost analysis;

- design and finite element analysis;

- materials development and validation;

- pilot-scale manufacturing and prototyping and;

- supplier assessment.

To find out more, see our full range of services or call 01246 266244.

Share this article

Found this article useful? We have a full range of services to help you...

Market Intelligence

We provide impartial market intelligence and advice that is used by companies, trade bodies and governments to help inform business-critical decisions.

Understanding markets...

Materials Characterisation & Testing

We have an extensive suite of testing facilities for characterising polymers and composites, coupled with the necessary expertise to interpret and advise upon test results.

Testing composites...

Pilot-Scale Manufacturing & Prototyping

Our suite of pilot-scale manufacturing facilities are at your disposal - prepregging, compression moulding, resin transfer moulding, injection moulding, and many more.

Making composites...About the author